welcome to Henan Pingyuan Mining Machinery Co., Ltd.

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

FYBS1530

PK

84741000

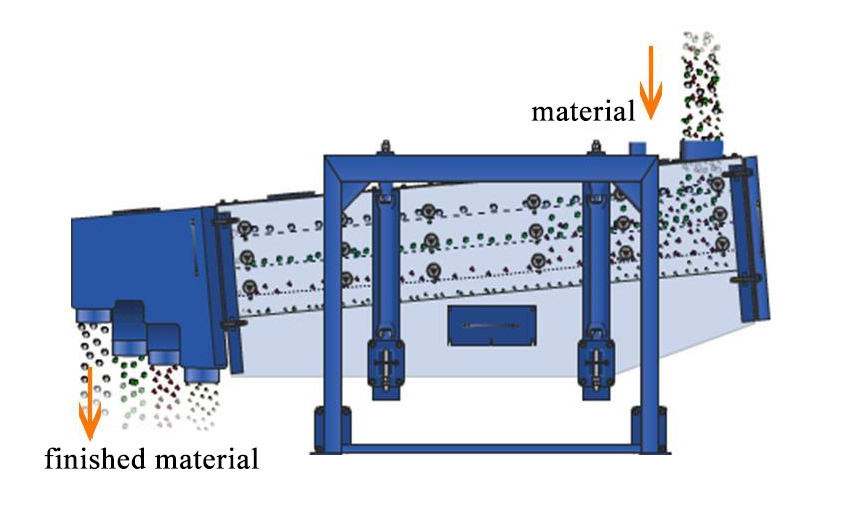

Tumbler screen machine adopts high-efficiency cleaning screen device to prevent clogging of screen holes.

Its screening accuracy and efficiency meets all fine and ultra-fine powder and particulate materials, through the square swing vibrating screen, the vibrator is vibrated and the swing motion is transmitted to the screen surface, so that the material is quickly dispersed in front of the screen to achieve the purpose of efficient screening.

1. Large effective screening area and high screening efficiency

2. The material moves on the screen for a long time to ensure optimum screening accuracy and output

3. Adopt high-efficiency cleaning screen device to prevent clogging of screen holes

4. With a unique structural design, it supports easy replacement of screens and reduces maintenance

5. Airtight dust removal, safe operation and low noise

6. Reasonable design, long service life, simple structure, stable operation, energy saving and environmental protection

The proper configuration of the swing vibrating screen depends on following information:

1. Name of material: ____

2. Bulk density:____ t/m3

3. Feeding capacity: ___t/ h

4. Screen layer number: ____ layers

5. Screen mesh size for each layer: ____mm ____ mm ____ mm

6. Voltage: ____V, Frequency: ____HZ, 3 phase

| Model | Effective Screening Area (m2) | Power (kW) | Slope Angle (°) | Layer No. | Screening Speed (r/min) | Vibration Amplitude (mm) |

| FYBS1030 | 3 | 3 | 5-8 | 1-5 | 180-260 | 25-60 |

| FYBS1036 | 3.6 | |||||

| FYBS1230 | 3.6 | 4 | ||||

| FYBS1236 | 4.32 | |||||

| FYBS1530 | 4.5 | 5.5 | ||||

| FYBS1536 | 5.4 | |||||

| FYBS1830 | 5.4 | 7.5 | ||||

| FYBS1836 | 6.48 | |||||

| FYBS2030 | 6 | 7.5 | ||||

| FYBS2036 | 7.2 |

Note: All the parameters are for reference only, we can design and manufacture as per your requirements.